Magnesium Oxide Cement Association

Foreign Exchange to China Trip Report

December 1-14, 2019

December 19, 2019

Introduction

In an effort to further the Magnesium Oxide Cement Association (MOCA) partnership with the China Magnesite Material Association (CMMA) and factories within the many provinces of China, several MOCA members visited China in December 2019. The following members of MOCA were participants on the trip: Peter Francis (MOCA President), Mike Van Geyn (MOCA Technical Director), Jarrett Davis (MaxLife Industries) and Linjing Zhao (MOCA, CMMA and Shandong Lanchuang Trade & Economy Co. Ltd.). The goal of the trip was for MOCA to continue its partnership with the CMMA in attendance of their annual conference, development of the Chinese production standards, visit CMMA member factories, develop a trade agreement, inspect export-ready MOCA member production groups and raise awareness for the work that MOCA and other organizations are doing within the ASTM work groups to develop an international standard for Magnesium Oxide ceramic cement products and their use.

China Magnesite Material Association (CMMA) Annual General Meeting – Dec. 2-4, Haikou China.

MOCA members attended their 5th CMMA Annual General Meeting in as many years, further bolstering our connection to the officially recognized industry association within China. This participation allows MOCA to keep abreast of current events and push requirements for consistently made, good-quality products while also building support for our standards development work at ASTM International.

As has become custom, MOCA participated in and was invited to speak at the break-out session specific to MgO board products joined by approximately twenty (20) export ready companies and industry experts, which included presentations by Professor Tu, Professor Gao and Engineer Zhi. Discussions covered details of making quality boards, problems with measuring Chloride ion concentration, complying with the Chinese standards, along with group questions and answers.

Annual Attendance of the 2019 CMMA Annual General Meeting; December 2019.

Highlights of the break-out session include the following:

- The Chinese produced MgO, and related products, approximated market size was 100 billion yuan ($14,000,000,000 US Dollars) in 2018.

- Cao Chankun, Vice-President of the CMMA parent association, National Center for Timber products, indicated more support for MgO products and for product development support within the organization.

President Lyu of the CMMA has committed to attend the next ASTM Work Group meeting in Boston on March 31, 2020. - Liu Wenjie discussed new Research & Development projects and also gave a progress report on the new CMMA sulfate board standard. This standard is being developed separately from the current Magnesium Chloride standard that is already published. Expectation for the sulfate standard is to be published within the coming year.

- Several Chinese members commented on the need for more support of the ASTM International work, by contributing to standards and attending the Work Group meetings that occur bi-annually.

- It was noted that during 2019, the District of Beijing had threatened to ban MgO boards within Beijing City due to poor-quality materials and the frequency of occurrence. CMMA went to work and was able to forestay this action by committing to increase efforts to improve quality and consistency with standards from within China.

- Peter Francis gave a report on the current ASTM progress along with its benefits in helping to keep non-compliant materials from entering markets around the world. One of MOCA’s primary goals is to ensure that market growth around the world is attainable by ensuring that quality boards are delivered meeting an acceptance criteria by many governmental inspection agencies, which would help to alleviate the poor quality issues that have already occurred within several world markets.

- Mike VanGeyn spoke about inputting Quality Control procedures and manuals as well as developing Third-part auditing requirements for acceptance.

- Jarrett Davis commented on his experience with consistency of boards received being erratic and talked about the size and growth of the market opportunity within North America. He further discussed the status of the United States tariffs that have been enacted in which the current levels should not deter from further market development at this time.

MOCA was well received, and all attendees agreed that there was a need for well developed standards and high product quality to improve the reputation and profitability of MgO board products world-wide. There was some confusion about the board specifications required for the North American market as many producers make products to suit customer specifications and do not have standard product offerings for buyers to chose from. This creates some confusion in the market as we try to educate consumers in a developing industry.

Factory Visits, December 4-12

Following the CMMA AGM, MOCA representatives toured eight export-ready factories visiting 10 cities from Hainan, Guangdong, Jiangsu, Shandong and Liaoning Provinces, Beijing and Shanghai. The objective of the visits was three-fold: information gathering on production methods for standard development, quality control procedures and implementation and to determine if companies would embrace and be eligible for production under the MOCA supply chain quality certification program.

Several of the factories are new, with computerized, automatic production lines. One of the automated lines was about to begin production, one has been in production for 3 months and 2 with a longer production history. This increase in investment and development in MgO board process technology is great news that we have been waiting for some time to see. Capacity is growing and quality becoming more consistent from compliant factories. The newest factory boasts in-process data collection with a 4,000 board per line per shift capacity. Most factories produce approximately 1000 ~ 1,500 boards per day.

Some of the factories we visited specialize in high strength and exterior rated boards. Some focus on decorative products while others offer custom formulations up to 12 ft. long. One factory provides panels for Hitachi elevator doors while another is experimenting with basalt and carbon fiber to make exterior panels for the high-speed trains which run at 340 kph.

Some factories have installed laminating lines to apply HPL and other finishes to MgO. These lines require exacting board tolerances and quality parameters which drive better production technologies.

All of the factories visited had ISO 9000 or better Quality Assurance systems, a working quality control lab and a relationship with one of the key consultants who provide technical support for formula development and testing. Some had third party auditing of their quality control manuals and some had third party auditing of products produced. They are all prepared to follow the MOCA QA system currently being developed by Mike VanGeyn based on advice received from the experts and consultations with factory technical and lab personnel. CMMA’s lab has agreed to participate in this process by reviewing our work and providing access to large samples of test reports.

In addition to the factories, we toured a mining and ore calcining operation, fire door core factory, the CMMA lab in Beijing, had a meeting with Intertek, and met with a company using MgO to bind all types of waste into durable cement products.

We witnessed and videoed a chloride test being conducted, a copy of which will be made available to MOCA members. Currently, chloride ion tests use a water-soluble method as it more closely follows the stresses placed on boards in real life; however, some feel that this test probably returns an elevated result due to additional chloride ions being made available due to the small particle size used to perform the test. An alcohol method developed in Taiwan is reported to return more accurate results, but we were not able to learn the delta between these two methods as this comparative study has not been funded at the time of our visit.

One of our goals is to have the factories and MOCA own their own Intellectual Property and test reports, rather than their customers, which will increase product knowledge, the availability of conforming product, decrease supply times and reduce overall costs. The Canadian Construction Materials Centre (CCMC) will allow for similar products from multiple factories to use the same Tech Report and we will be able to assist with the creation and adoption of a new Acceptance Criteria for ICC codes that may also be used for this consolidated approach.

Intertek is able to provide services for sampling, auditing to the MOCA QA manual and conduct many AC386 referenced and fire tests at their labs in Shanghai and Guangzhou. Using all of the accredited labs available to us will provide a very robust system to limit the export of non-complaint boards. Of course, third party testing only shows us what has happened. All of the factories visited perform testing after the 1st, 2nd and 3rd curing phases, test reports that can be shared with MOCA to show compliance for individual orders.

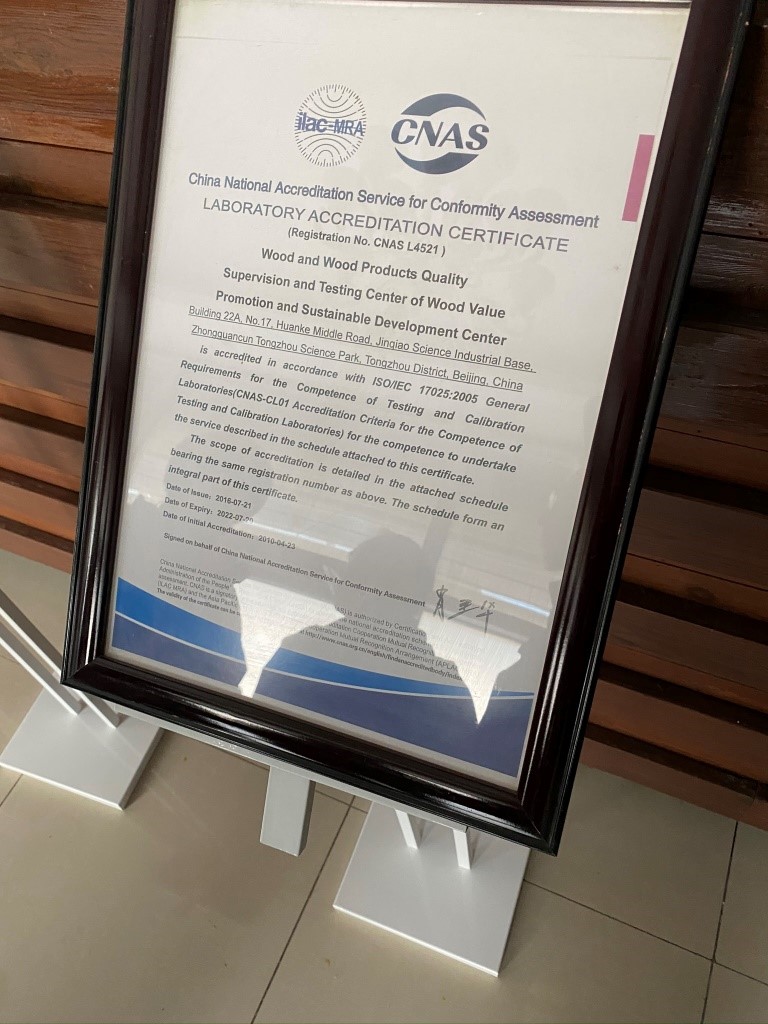

The CMMA lab, which is operated by the Wood Value and Sustainable Development Center, has the highest Government certification in China, is accredited to ILAC and is compliant with ISO 17025. They are fully supported with Government funds and this year took delivery of a room full of test chambers for long term environmental and other tests to supplement their existing well-supplied chemical lab and material property testing services. CMMA’s lab will provide an appendix with all test results along with their formal certified test report on all orders placed using the MOCA QA supply channel. CMMA’s lab can collect samples, work from entrusted samples or we can hire agencies like Intertek to collect them, further securing the chain of custody and validating production for the end user.

As it will take a few years before the ASTM standards have been developed, MOCA is in the process of improving its interim “industry standard” that draws from the AC 386 and existing Chinese standards and with the knowledge obtained from this trip. This MOCA standard will provide CMMA’s lab, third party agencies such as Intertek and MOCA member buyers, a formal testing standard to reference and work to. It is our goal that the MOCA standard will be the foundation for the ASTM standard and will be considered and voted on by the E06.21 committee in the coming future.

In order to provide the best QA system all MOCA compliant factories will be required to:

- Purchase MgO powder and other raw materials from approved suppliers.

- Raw materials shall be the appropriate grade and comply with published Chinese standards as appropriate.

- Test raw materials on a batch basis.

- Adjust the formula based on reactivity and ambient temperatures.

- rack and record curing temperature and humidity for 1st and 2nd stages.

- Test boards after 1st, 2nd and 3rd curing stages.

- Calibrate lab and production equipment on a regular schedule.

- Maintain quality control records of all tests and inspections associated with production batches.

- Provide access to test reports and QA records during quality audits.

- Remove and sequester non-compliant products, many of which are being used for cover sheets and making pallet stock, samples etc.

- Comply with batch traceability and finished product marking requirements.

Typical factory tests will most likely include:

- Density

- Water content

- Screw withdrawal

- Wet and dry bending strengths

- Chloride content

- Halogenation

According to the CMMA lab they are not aware of any boards failing the Chinese freeze thaw and non-combustible tests.

Funds have been made available for a translator for speedy and accurate translations to and from Chinese to English. This is significant and will improve and accelerate our work at MOCA and ASTM allowing for better coordination around the globe. Thanks to MaxLife Industries for this support.

Overall Trip Summary

The trip to China exceeded the MOCA member’s expectations and achieved the following goals and objectives;

- Maintained credibility of MOCA with the CMMA and individual manufacturers

- Obtained participation and cooperation with Chinese producers with the development of the ASTM standards

- Located a series of manufacturers that are capable of producing board products that comply with the quality expectations of the North American market and the MOCA supply chain quality program, and established a relationship with these companies

- Gained a better understanding of board manufacturing and quality control methods

We intend to continue this work by continuing to participate in annual CMMA conferences and develop a larger group of eligible manufacturers in the years to come. If you are interested in participating in upcoming trips, development of standards or Quality Control procedures, then please reach out to the MOCA office as committees are being developed now. Put your membership and interest in the Magnesium Oxide Cement Association and your industry to work for you. As you can see, the future is bright, and we want to hear from you as to how we can assist your business going forward.

Happy Holidays!

Peter, Mike, Jarrett & Linjing

Figure 1 CMMA lab certification

Figure 1 CMMA lab certification

Figure 2 CMMA lab, new toys

Figure 2 CMMA lab, new toys

Figure 3 CMMA break out meeting group

Figure 3 CMMA break out meeting group

Figure 4 Typical sample library

Figure 4 Typical sample library

Figure 5 Insulated panel options

Figure 5 Insulated panel options

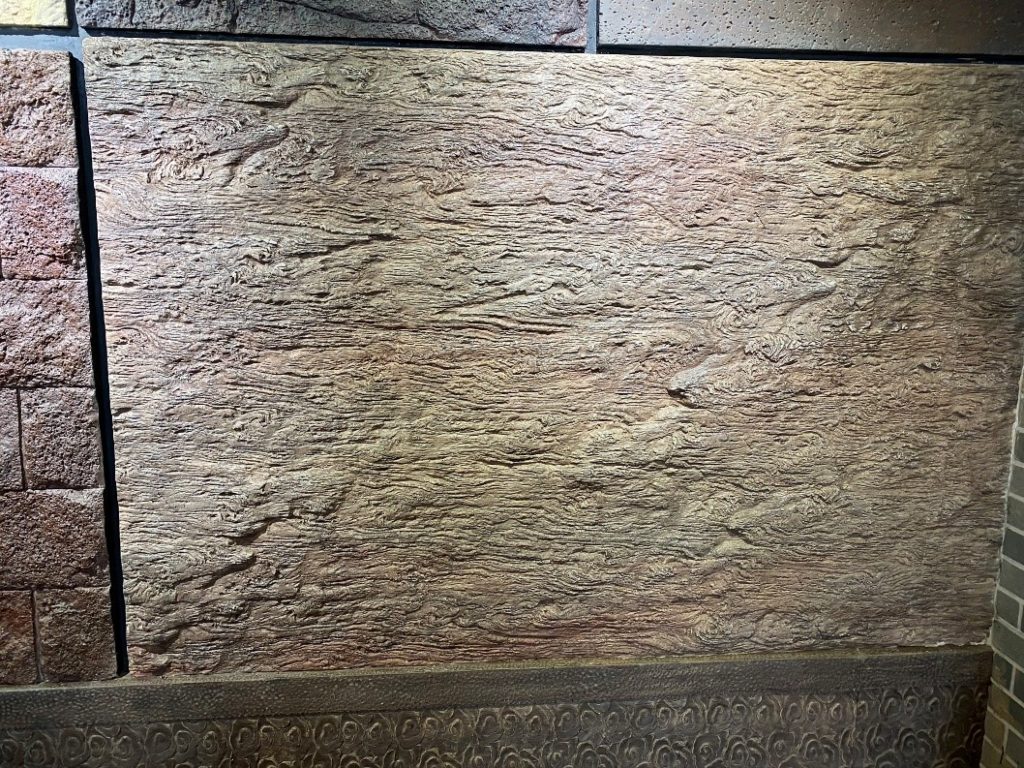

Figure 6 Decorative overlays

Figure 6 Decorative overlays

Figure 7 non-conforming mago pallets

Figure 7 non-conforming mago pallets

Figure 8 Cloride test

Figure 8 Cloride test

Figure 9 New SS automated line

Figure 9 New SS automated line

Figure 10 Automated raw materials mixing

Figure 10 Automated raw materials mixing

Figure 11 New curing chambers

Figure 11 New curing chambers

Figure 12 New processing equipment

Figure 12 New processing equipment

Figure 13 Magnesite mine, one of many

Figure 13 Magnesite mine, one of many

Figure 14 Magnesite ore

Figure 14 Magnesite ore

Figure 15 – Calcining kilns, single hearth

Figure 15 – Calcining kilns, single hearth

Figure 16 – New Calcining kiln, suspension type

Figure 16 – New Calcining kiln, suspension type

Figure 17 – Long term weathering, 15 yr old boards, 4 typhoons

Figure 17 – Long term weathering, 15 yr old boards, 4 typhoons

Figure 18 – Laminating clean room

Figure 18 – Laminating clean room

Figure 19 – Decorative cast panels

Figure 19 – Decorative cast panels

Figure 20 – Decorative items, all of it

Figure 20 – Decorative items, all of it

Figure 21 – Decorative / functional cast furniture

Figure 21 – Decorative / functional cast furniture

Figure 22 – Foamed magnesia cement, hydrophobic

Figure 22 – Foamed magnesia cement, hydrophobic

Figure 23 – Another automated mixing system

Figure 23 – Another automated mixing system

Figure 24 – Your team, hard at work

Figure 24 – Your team, hard at work

小赵您好!

争取北美玻镁平板市场是中国菱镁行业协会努力的目标。前两年,Peter先生没有把市场做大的第一原因是我国生产企业没有统一的标准,质量问题多;第二原因是北美没有产品进口标准。没有统一的标准检验玻镁板质量,影响玻镁板市场的健康发展。

Peter先生在努力玻镁平板的“北美标准”对北美市场的健康发展很有必要。玻镁平板生产企业应该积极配合,实现共同发展的目的。

关于制订玻镁平板的“北美标准”,我认为有以下几点需要统一认识:

1、采用氯氧镁水泥,还是硫氧镁水泥?

氯氧镁水泥历史超过100年,硫氧镁水泥只是近10年时间发展起来的新品种。氯氧镁水泥相结构稳定,518或318相,而硫氧镁水泥的相结构尚不稳定,在日晒雨淋的环境下存在龟裂风化现象。

氯氧镁水泥的缺点是氯离子含量,若游离氯含量小于3.5%,氯氧镁水泥板不会返卤,不影响使用。氯含量大于3.5%,在长期高湿的环境下会出现吸潮返卤。

所以,本标准不规定采用氯氧镁,还是硫氧镁,或者是氯硫混合物。只要游离氯含量小于3.5%,浸水7天,软化系数≥85%,无返卤现象,即可放心使用。

2、玻镁平板应该按密度分为轻质板和重质板两个系列。

a、密度900±50kg/m³为轻质板,用于室内墙板或装饰板。

b、密度1200±50kg/m³为重质板,用于室外或强度要求高的用板。a板和b板各自制定技术指标,增加用户使用的灵活性,保证结构强度要求。

3、玻镁平板的吸水率、含水率、干缩率、湿胀率等指标严重影响玻镁平板的尺寸稳定性,应越小越好。解决玻镁板与玻镁板拼接缝的开裂问题,比强度指标更重要。

4、泛霜、返卤指标

氯氧镁水泥的游离氯大于3.5%时,在高湿度环境下会出现泛霜、返卤现象,游离氯小于3.5%就能保证无返霜、返卤。所以游离氯的指标很重要。

5、燃烧性能

不管是氯氧镁水泥还是硫氧镁水泥,都应达到不燃A1级防火要求。

6、座钉力,与玻镁平板的密度有关。密度越大,座钉力越强,所以外墙板的密度大,座钉力好,因为外墙板受风力影响,座钉力大于室内板。

7、产品名称

a、玻镁平板,是玻璃纤维增强镁质水泥板简称。

b、镁质水泥平板,是突出水泥属性,与硅酸盐水泥一样。

c、镁质胶凝平板,是将水泥改为胶凝,不用水泥两字。是对硅酸盐水泥的区别。

我认为用《镁质胶凝平板》代表氧化镁、氯化镁、硫酸镁的组合和属性。有利市场发展和效益体现。

以上设想供讨论完善。

欢迎Peter先生指导!

支洋波

2019/12/9

From Zhi Yangbo, perhaps the first businessmen to make magnesia cement boards and a MOCA member.

Machine translation, please feel free to correct.

Hello Xiao Zhao!

Striving for the North American glass magnesium flat plate market is the goal of the China Magnesite Industry Association. In the first two years, the first reason why Mr. Peter did not enlarge the market is that Chinese manufacturers have no unified standards and there are many quality problems; the second reason is that there are no product import standards in North America. There is no uniform standard to test the quality of glass magnesium board, which affects the healthy development of the glass magnesium board.

Mr. Peter is working hard on the “North American Standard” of glass magnesium flats, which is necessary for the healthy development of the North American market. Glass magnesium flat plate manufacturers should actively cooperate to achieve the goal of common development.

Regarding the formulation of the “North American Standard” for glass magnesium flats, I believe that the following points need to be recognized:

1. Use magnesium oxychloride cement or magnesium sulfoxide cement?

Magnesium oxychloride cement has a history of more than 100 years, and magnesium oxysulfate cement is only a new variety developed in the past 10 years. The phase structure of magnesium oxychloride cement is stable, phase 518 or 318, while the phase structure of magnesium oxysulfate cement is not stable, and cracking and weathering occur in the sun and rain.

The disadvantage of magnesium oxychloride cement is the chloride ion content. If the free chlorine content is less than 3.5%, the magnesium oxychloride cement board will not return to halogen and will not affect the use. Chlorine content is greater than 3.5%, and it will absorb moisture and return to halogen under long-term high humidity environment.

Therefore, this standard does not specify the use of magnesium oxychloride, magnesium thioxide, or a mixture of chlorine and sulfur. As long as the free chlorine content is less than 3.5%, soak in water for 7 days, the softening coefficient is ≥85%, and there is no halogen return, you can use it with confidence.

2. Glass magnesium plate should be divided into two series: light board and heavy board according to density.

a Density of 900 ± 50kg / m³ is a lightweight board for indoor wall panels or decorative panels.

b. The density is 1200 ± 50kg / m³, which is a heavy-duty board. It is used for outdoor or high-strength boards. A board and b board have their own technical specifications to increase the flexibility of users and ensure the structural strength requirements.

3. The water absorption, water content, dry shrinkage, and swelling rate of glass magnesium plates seriously affect the dimensional stability of glass magnesium plates, and the smaller the better. It is more important to solve the cracking problem of the splicing seam between glass magnesium plate and glass magnesium plate than the strength index.

4.Frost frost and halogen return index

When the free chlorine of magnesium oxychloride cement is more than 3.5%, frosting and halogen return will occur under high humidity environment. Free chlorine is less than 3.5% to ensure no frost and halogen return. So the index of free chlorine is very important.

5. combustion performance

Regardless of whether it is magnesium oxychloride cement or magnesium oxysulfate cement, it should meet the requirements of non-combustible A1 fire protection.

6. The nail force is related to the density of the glass magnesium plate. The higher the density, the stronger the nail strength, so the density of the external wall panel is high, and the nail strength is good, because the external wall panel is affected by the wind, and the nail strength is greater than the indoor panel.

Product name

a. The glass magnesium plate is an abbreviation of glass fiber reinforced magnesium cement board.

b. Magnesium cement slabs have outstanding cement properties, just like Portland cement.

c. Magnesium cemented slab is to change cement to gel instead of cement. It is the difference to Portland cement.

I think the “magnesium gelling tablet” represents the combination and properties of magnesium oxide, magnesium chloride, and magnesium sulfate. Conducive to market development and efficiency.

The above assumptions are for discussion.

Welcome Mr. Peter for guidance!

Zhi Yangbo

2019/12/9